A short video showing the various components. It is a self adjusting pressure plate which was an interesting discovery for the first time!

Following an endless desire to know more and go faster!

A short video showing the various components. It is a self adjusting pressure plate which was an interesting discovery for the first time!

I recently bought clutch cover bolts online and ironically 6 packages came from a GM online dealer. To my disappointment each only had 1 m6 bolt within it.

This is the GM throttle pedal. It isn’t ideal because of the angle that it mounts but some fabrication can make it work. Because the ecu is drive by wire a new pedal was needed. Here are a few pictures showing the pedal

To get the motor off of the pallet I wanted to build a “skate” to hold the engine and trans. My goal is to add wheels to the engine and the trans and have an assembly that can move around and probably running.

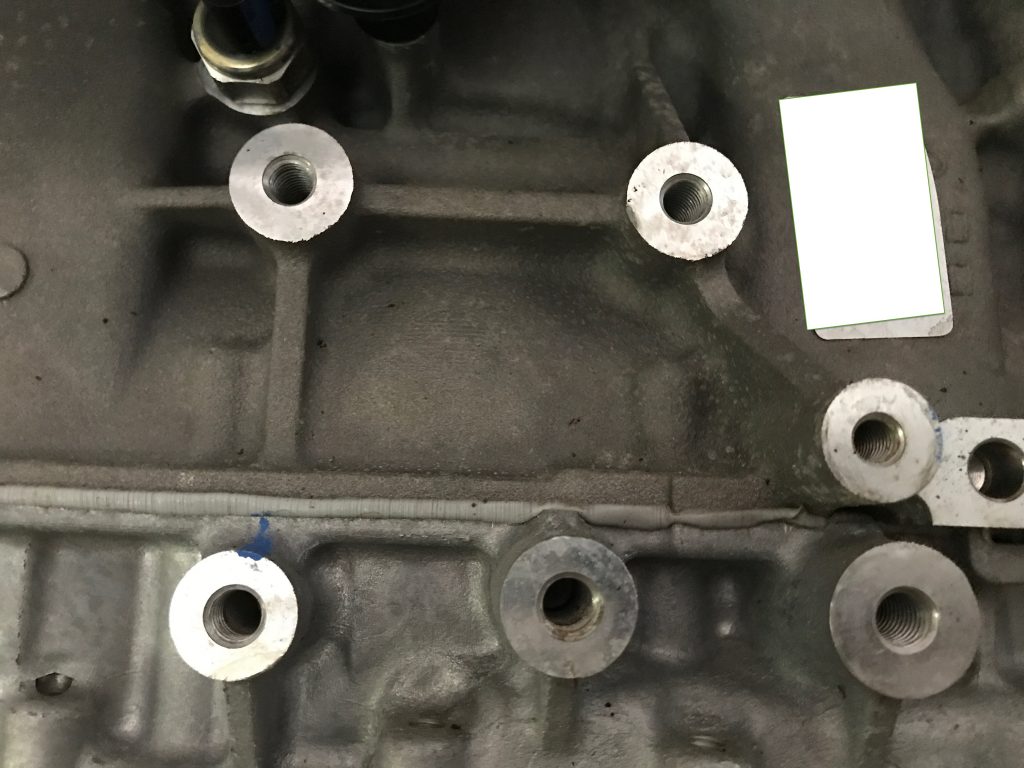

This is the passenger side of the engine that a mount needs to connect towards

This is the drivers side of the engine.  This is what I suspect the mounting plates will look like.

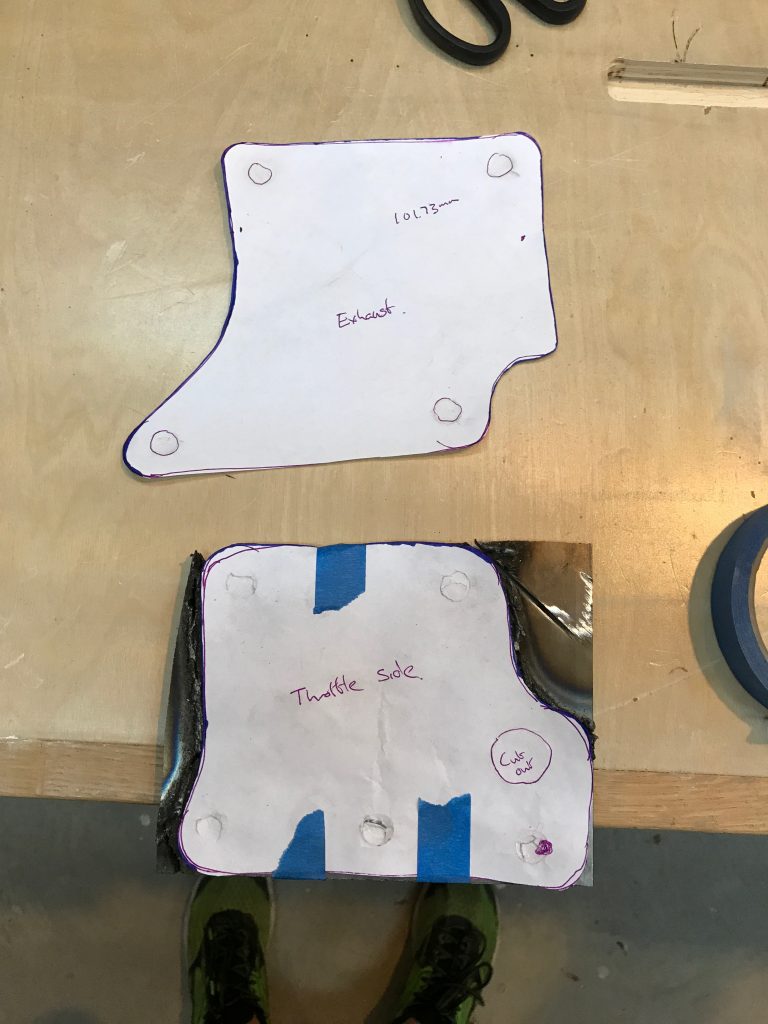

This is what I suspect the mounting plates will look like.

I tried to mount the paper version on a piece of steel and trace it out. My goal was then to cut it out with the plasma cutter. Unfortunately 25 amps was not enough and the breaker would trip at that point. A 4.5″ angle grinder did a good job and soon after I bought a bunch of flap disks with the intent of getting them to being really smooth and pretty. Next up I need to measure and cut spacers as the plates will not bolt flush to the engine block.

More to come..

The hardest to find parts is anything related to the manual transmission. It’s really like looking for a needle in a haystack.

The hardest to find parts is anything related to the manual transmission. It’s really like looking for a needle in a haystack.

I bought a fidanza flywheel after refusing to pay $800+ for a factory flywheel. My entire life I have wanted a lightened flywheel so it was an attractive option.

The problems..

Firstly the flywheel bolts are custom. Thankfully Tim at Zzperformance hooked me up. I will admit that looking for M11 bolts was a pain in the ass!

Secondly the pilot bearing is a big question mark. It doesn’t look like the factory would fit and there isn’t much information about what to do. More to come on that front after I talk to Fidanza.

Lastly I have called a few dealers trying to find a factory clutch and pressure plate. Many of them don’t see it in the parts catalog which is frustrating. I will most likely just buy it from Zzperformance.

If you decide to go LTG I would recommend just buying the clutch masters at from zz and be done. Spending hours trying to find information for simple things is not worth the savings!

After a large amount of research I was frustrated by the poor development of the LTG motor by General Motors. The initial launch was so strong but the follow through of the crate engine was very poor.

My hope is that I can add some content for anyone with an Ecotec build that isn’t willing to pay $8k for a crate motor, $4k for a manual trans, $2k for an ECU and a good few other packages to get things going.

I managed to talk to Andy at Swap Specialties and he gave me a good amount of faith in the process and their development.The order at the end of the day was for an almost fully loaded harness. – http://swapspecialties.com/product/gm-echo-tec-standalone-harness/

One aspect that Andy mentioned was their ECU and harness doesn’t require the fancy PWM fuel pump controller and a dead head pump. This is ideal because I have a fuel cell and would not want to modify the filler mechanism.

Lead time is 4 weeks but there is plenty to do and buy before I need the harness!